Understanding Your Ford 8N's Firing Order

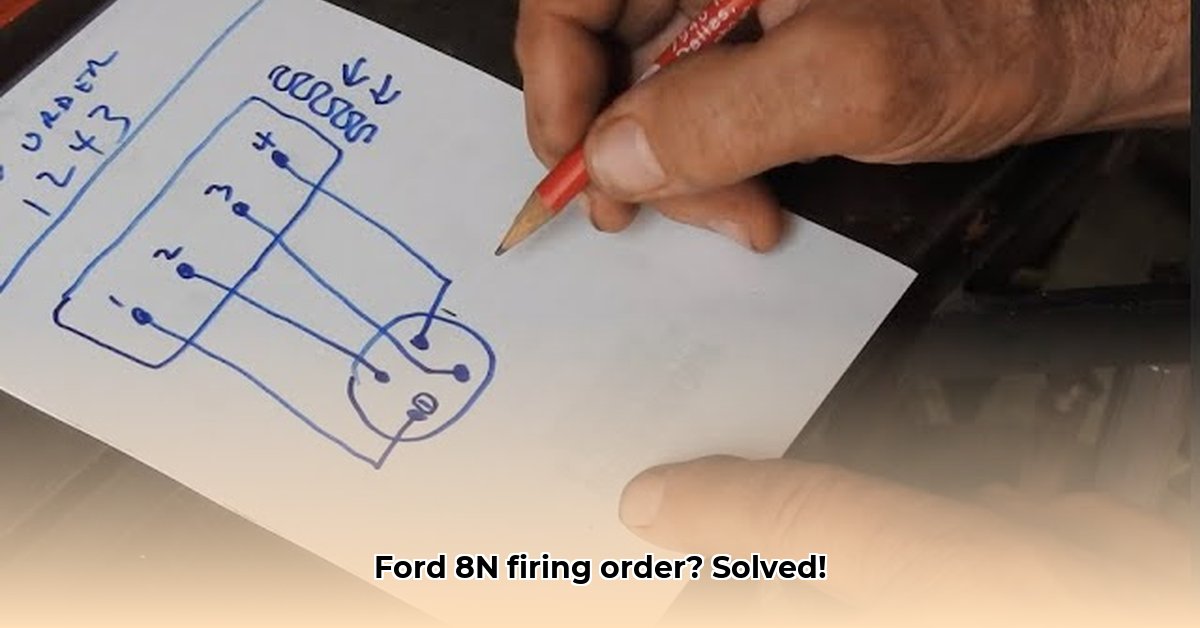

Is your Ford 8N tractor running rough, sputtering, or refusing to start? A common culprit is an incorrect firing order. This guide will walk you through understanding and correcting the firing order on your 8N's four-cylinder engine, ensuring smooth and efficient operation. The correct sequence is 1-2-4-3. Why is this important? Proper ignition timing ensures balanced power strokes and minimizes vibrations, maximizing engine performance and longevity. Ignoring this can lead to decreased power, engine damage, and frustrating downtime. For more detailed 8N specifications, check out this helpful resource.

Identifying the Cylinders

Before you start working with the ignition system, you need to correctly identify each cylinder. The Ford 8N has an inline engine arrangement, making identification relatively easy. Cylinders are numbered sequentially from the front (Number 1) to the rear (Number 4) of the tractor.

The Distributor Cap: Directing the Spark

The distributor cap is the central component of your 8N's ignition system. It routes high-voltage electricity to each spark plug in the correct order. Wires within the distributor cap are typically arranged counter-clockwise. Each wire corresponds to a specific spark plug and cylinder according to the 1-2-4-3 firing order. A miswired cap is a common cause of engine misfires. Remember to double-check your wiring!

Troubleshooting Common Ignition Problems

If your Ford 8N is experiencing misfires, low power, or starting difficulties, systematic troubleshooting is key. Here's a step-by-step approach:

Inspect Spark Plug Wires: Carefully examine each wire for cracks, fraying, or corrosion. Damaged wires can prevent a spark from reaching the plug, resulting in a misfire. Replace any damaged wires immediately for reliable ignition. This simple check often solves the problem.

Check Spark Plugs: Inspect the spark plugs for fouling (carbon buildup), wear, or physical damage. Fouled or worn plugs need replacing for optimal performance. Ensure correct spark plug gap for the best ignition.

Verify Distributor Cap Connections: Tightly secure all spark plug wires at both the distributor cap and spark plug terminals. Loose connections interrupt the spark, causing misfires. A firm connection is crucial for reliable ignition.

Test the Ignition Coil: A faulty ignition coil can prevent sufficient spark creation. While testing this component requires more mechanical knowledge and tools, a malfunctioning coil is a potential source of misfires. Consider professional inspection if you're unfamiliar with this step.

(Advanced) Ignition Timing: If the above steps don't resolve the issue, ignition timing might be off. This requires advanced knowledge and specialized tools and often warrants a professional mechanic's assessment.

The 6V to 12V Conversion: Considerations and Potential Pitfalls

Many Ford 8N owners upgrade their tractors from a 6-volt to a 12-volt electrical system. This upgrade requires careful attention. Improper conversion can damage the ignition system. Crucially, you'll need additional components like a ballast resistor to protect the ignition coil from the increased voltage. Using parts specifically designed for a 12V 8N system is vital. Always consult a reliable guide or experienced mechanic for this modification. Don't risk damaging your tractor's electrical system through improper installation.

Preventative Maintenance: A Proactive Approach

Regular preventative maintenance dramatically reduces the chance of ignition system problems. Periodically inspect your spark plug wires, distributor cap, and spark plugs. Replacing worn components proactively prevents costly repairs and maximizes the lifespan of your engine. Routinely inspect your 8N’s vital systems to prevent small problems from becoming major headaches.

How to Troubleshoot Ford 8N Tractor Engine Misfire After 6V to 12V Conversion

A misfiring engine after a 6V to 12V conversion often stems from issues within the ignition system. Here's a systematic approach:

Fuel System Check: Start with the basics. Inspect your fuel lines for cracks, blockages, or leaks. Replace your fuel filter if needed. Ensure the fuel tank and pickup aren't clogged.

Thorough Ignition System Inspection: This is the most likely source of problems post-conversion. Check the integrity of the coil using a multimeter. Inspect the points, condenser, and distributor cap for wear and tear. Clean and adjust points as needed. Remember to check the components' compatibility with the higher voltage of the 12V system. Replacing faulty parts is crucial.

Carburetor Cleaning and Adjustment: A dirty carburetor can affect fuel delivery, mimicking ignition issues. Thoroughly clean and adjust the carburetor according to the manufacturer's specifications. Improper fuel delivery can lead to misfires.

Compression Test: Low compression in any cylinder indicates potential internal engine problems. This test is best done by a mechanic with appropriate equipment.

Electrical System Review: Check all wiring for damage, corrosion, or loose connections. Verify that the ignition components are receiving the correct voltage. Loose or damaged wiring often causes intermittent problems.

Vacuum Leak Detection: Vacuum leaks disrupt engine performance. Check all vacuum lines and gaskets for leaks using specialized tools or techniques.

Key Takeaway: The 1-2-4-3 firing order is crucial for proper engine function. Understanding this sequence, along with diligent maintenance, will keep your Ford 8N running smoothly for years to come. A little preventative maintenance goes a long way. Regularly servicing your 8N’s ignition system prevents costly repairs in the long run.